Vintage Woodworks

Architectural Details Direct - 903-356-2158

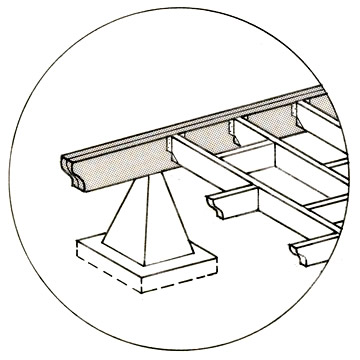

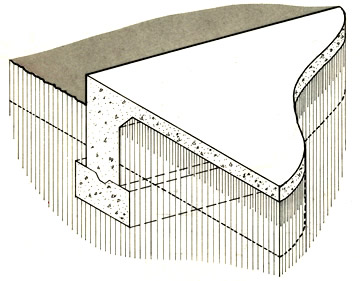

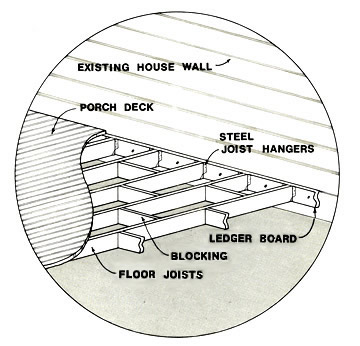

Home Contact Us Help Shipping Shopping Cart 903-356-2158 Porches Doors Gables Brackets BeadBoard Mouldings Azek Photos Our Story Guarantee Customer Comments Product Options A-Z Index Pictorial Index Foundation & Floorby an adequate foundation. Foundation Considerations Most porch foundations will be either pier and beam or concrete slab construction. We recommend pier and beam with AZEK Porch Boards. This will be much more traditional than a concrete porch and we think much more enjoyable for you and your family. Either way, please be aware that your finished porch floor should be slightly below the door threshold to permit proper water drainage and should slope gently away from the house. Please seek professional assistance in determining the proper foundation for your location and situation. The most important consideration with any foundation is that it be stable and able to withstand any movement the underlying ground may experience. Frost heave (the tendency of frozen ground to push upward) must always be addressed where the ground freezes in winter. Pier and Beam Foundation Typically used with a structural wooden framework (floor joists) covered by wood, composite, or PVC flooring. Joists are supported by beams (girders), which are in turn supported by short posts or columns (piers). Each pier typically sits atop a concrete pad (footing) set into the ground below the frost line.  Joists Cantilevered Over Beam Cantilevered Joists Joist framework can rest atop the Beams, as shown above. This permits overhanging the Beam. If the crawl space under the porch is to be left open, overhanging the Beam presents a neater appearance, as the Beam is recessed. If the crawl space is later enclosed with underpinning an overhung Beam is less tedious to work with. Joist Hangers Conversely, joists can be hung with readily available metal Joist Hangers directly to the side of the Beam, as shown below. If the piers are pyramidal in shape or if their tops are wider than the Beam, they may extend beyond the face of the Beam. If so, this will make it more difficult to enclose the crawl space with underpinning.  Joists Hung on Beam Face Treated Lumber, please! Joists and Beams should be made of treated lumber to withstand the moist conditions they are subjected to. To allow proper water drainage, the foundation and joists should be built with a slight slope towards the front of the porch. Also, the floor boards should run from the back of the porch to the front. This will allow water to run down the boards and off the front of the porch. Therefore, it will be necessary to install blocking between the joists, as shown above, on which to fasten the flooring. Underpinning Underpinning is the skirting which conceals the foundation of many homes. It is most often used below the front edge of a porch floor and typically extends to the ground. This skirting is often made of lattice panels or sheet metal panels with a stamped pattern simulating brick or stone. These traditional skirting materials are usually available locally. A very effective underpinning can be created using PVC Beadboard. Others have used our Sawn Balusters as a unique and decorative underpinning. Concrete Slab Foundation Typically a solid, poured-in-place concrete structure. The resulting concrete floor may be used directly as the finished floor. Alternatively, tile, stone, brick, or other masonry-type finished flooring may be applied over the concrete. If so, it is very important to lower the finished height of the concrete to allow for the installed thickness of this floor. Slab Specifications The concrete slab, as it is commonly called, is strengthened with steel bars or wire running through its core. The slab is generally 3" to 6" thick. Concrete beams (footings) 10" to 16" wide and 12" to 36" deep are typically placed under its perimeter and occasionally through its length or width depending upon the size of the slab. Most people, unless they have experience in this area, will contract with a professional to "pour the slab."  Dotted line represents "frost line." Floor Framing If you are planning a Pier and Beam Foundation, then you will need to decide upon the size and spacing of your beams and joists. It is always preferable to err on the side of larger and closer, for you will want your porch floor to feel (and to be) very sturdy! Please seek professional advice in determining these important factors. Ledger Boards Where the floor joists meet the wall of the building to which the porch is to be attached, it is typical to have a ledger board, as shown below. This ledger board is fastened horizontally to the building, so as to receive the ends of the floor joists. It, as well as the rest of the floor framing, should be of pressure treated lumber, as mentioned earlier.  Ledger Board fastened directly to the building. This ledger must, of course, be fastened securely into the structure of the building, as it will support considerable weight. We recommend the use of steel Joist Hangers as the method of attaching joists to the ledgers, both for their ease of installation, and for their strength. Direction of Flooring It is traditional for porch flooring to run perpendicular to the house on all sides, with a 45 degree seam where the flooring turns a corner, as shown below. We feel strongly about this and are concerned you will be disappointed in the 'deck like" appearance of porch flooring that all runs in the same direction on a porch that turns a corner. Blocking If you install blocking between each pair of framing joists the floor joists can run perpendicular to the house, as is standard. The drawings above illustrate this. Note that the blocking can be staggered for easy installation of the blocking when using tongue and groove flooring, as the flooring fasteners will not show.  You can easily modify the underlying framing (see drawing below) to permit a single diagonal Porch Board at the corner seam to which your regular corner Porch Boards are butted. This makes it easier to install the Porch Boards, as you avoid having to keep Porch Board pairs as tightly matched at the seam. We think this creates a more professional final appearance.  The drawing above illustrates the most typical way to frame the corner of a porch by using a pair of diagonal floor joists at the corner. As shown, shorter joists die into this pair of diagonal joists. In the drawing above the dashed lines on either side of the diagonal joist pair represent 3/4" blocking which as been installed between each pair of shorter joists. (1-1/2" blocking can also be used.) This blocking serves two purposes. First, it locks the mitered end of each shorter jost into place to keep them from later twisting away from the diagonal pair of joists. Second, it increases the overall width of the diagonal joists to 4-1/2" (with 3/4" blocking) when measured perpendicularly across these joists. That 4-1/2" overall joist and blocking width is important because it allows a 3" wide diagonal porch board (net width after removing the tongue on tongue & groove boards) to be installed on top of the diagonal joists while also preserving 3/4" of exposed blocking on either side of the joists to receive the regular corner Porch Boards. The regular Porch Boards are mitered on one end and butted to this diagonal board. This method is only slightly more trouble at the framing stage but provides a more professional look for your porch corners. Installing Porch Boards (using the Diagonal Corner Flooring Board Method Described Above) Once the underlying framing is prepared, a diagonal corner flooring board is installed, centered on the diagonal corner joists (see drawing above). The end at the inside corner should be notched to fit around the house corner and the end at the outside corner should be pointed to create the corner of the flooring. Next, a pair of full width Porch Boards are installed at the outside corner, running perpendicular to each respective wall of the house. This first pair and all subsequent corner floor boards should be mitered at a 45 degree angle on the edge against the diagonal porch board. Cut this miter so that the groove side of these boards can be butted against the diagonal corner flooring board. Subsequent mitered Porch Boards should also be installed in pairs. Maintain even, symmetrical alignment from side-to-side on each pair for the tips closest the house. You can 'fudge' the space between boards ever so slightly to maintain this side-to-side symmetry. Floor Types Your choice of floor type will depend upon the type of foundation you choose (or vice versa). Pier and Beam foundations are typically used for wood, composite, and PVC floors, while masonry floors are normally laid over concrete slab foundations. Regardless of the material chosen for your floor, you should design your porch so that the front and side edges of the floor will be inside the line of the roof overhang. This will, obviously, keep your porch floor drier. Wood flooring Providing your joist blocking is spaced closely enough for adequate support, a very traditional wood floor can be made of 1 by 4 lumber. Many "old-timers" feel this lumber should not be "flooring" (with tongue & groove or shiplapped edges), as this will tend to trap moisture. Rather, they favor a premium grade of square-edged lumber, nailed down edge to edge. The resulting cracks between boards allow moisture to fall through to the ground below. These same old-timers avoid the use of pressure treated lumber for flooring, as it often warps badly. One of our owners has had good success using a high grade of 1x4 pressure treated pine for replacement boards, but this was installed before AZEK Porch Flooring was available. He will be changing to AZEK Cellular PVC Porch Flooring (see below) when it's time to replace the entire porch floor. The individual boards should run from the front to the back of the porch, as mentioned above. This will allow water to run down the boards and off the front of the porch. If the boards were to run the length of the porch, the cracks between boards would impede the flow of water! And as also mentioned above, be sure that there is a slope from the back of the porch to the front. Obviously, a premium grade of porch decking paint is required for any wood floor! Also, it is always a good idea to keep shrubbery trimmed well back from wooden porches, as this will keep the porch drier. Composite Flooring In recent years a number of man-made outdoor flooring products have come to market. Most of these are composites made of some sort of synthetic material mixed with wood fibers. Originally intended for decks, more recently some have been introduced that attempt to simulate wood porch boards. Unfortunately, these composites have fallen short of the promise of long and trouble free life. Early discoloration, unsightly scratches and staining, as well as stability problems have plagued these products. As they age, more and more of their shortfalls are becoming apparent. AZEK PVC Flooring - by far the best! Fortunately, there is a synthetic material that overcomes all of the shortcomings of composites - a PVC formulation from AZEK, the leading company for cellular PVC products to the building industry. AZEK's Porch Boards are almost 100% PVC, the same general material used extensively for many years for underground plumbing. However, you would never know this flooring is PVC . . . (read more and order a free sample). Masonry Floors As mentioned above, be sure to allow for the installed thickness of the tile, brick, stone, etc. you may wish to apply over your concrete slab. Porch Steps (Stairs) If your porch is far enough off the ground to require two or more steps, then you need Railings (also known as Balustrade) for safety. It is typical to use the same components that are used on the horizontal sections of Balustrade. Unless AZEK PVC Balusters and Bottom Rails are planned, it's important that the Bottom Rail have a sloped-top. |

|

| |||

| RELATED PAGES | |||

Introduction to Porches & Porch Parts | |||

Porch Parts Product Listings | |||

Porch Photos - Sec. A | |||

Free Personalized Porch Consultation | |||